Just as our lungs filter out contaminants in the air we breathe, air compressors rely on air filters to remove large debris, dirt, and other atmospheric air contaminants. Because of this, air filtration is critical for producing clean compressed air and ensuring a long product life for your compressed air system.

Aside from oxygen, atmospheric air contains water vapor, dust, dirt, and various other particles dependent on your operating environment. Additional contamination occurs if you are operating an oil-lubricated, reciprocating, or rotary screw compressor instead of compressor technology that delivers oil-free air, like a

centrifugal air compressor.

Since one cubic foot of compressed air contains millions of dirt particles, removing this contamination through a high-quality air filter will avoid damage to your compressor and keep valves from swelling. Otherwise, this will inevitably lead to increased vibration and a reduction in service life.

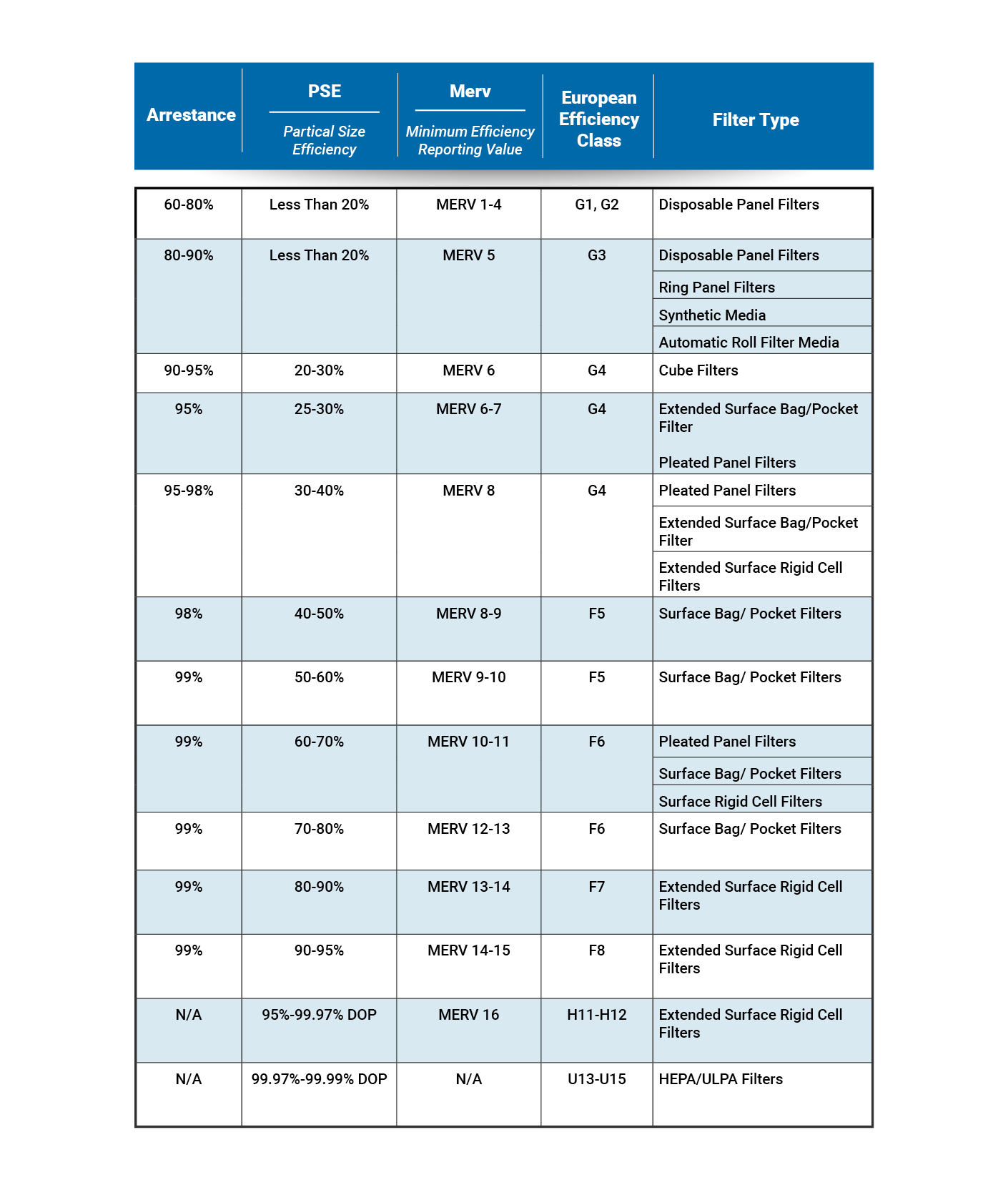

Understanding Air Filter Terminology

Below are the standard terms you will find when reviewing and comparing air filter elements.

- Particle Size Efficiency (PSE) – This measures the specific micron sizes in diameter and determines the air filter's ability to remove particles.

- Micron (micrometer) – This is a unit of measurement (one-millionth of a meter). For a particulate to be visible to the human eye, it needs to be at least 5 microns large. Therefore, the efficiency at which an air filter can capture microns is one of the most critical aspects when choosing an air filter.

- Arrestance – The percentage of debris or dust, by weight, that a filter element can stop.

- USA MERV (Minimum Efficiency Reporting Value) – This rating indicates how efficient a filter is at removing particulates and preventing them from entering the air stream. The higher the MERV rating, the more effective the filter is at trapping smaller particulates. However, it comes at the cost of creating more resistance to airflow, thus reducing system efficiency. The lower the MERV rating, the less effective the filter is at removing smaller particulates, but there is also less disruption in the airflow with these lower-rated filters.

- European Efficiency Class EN1822:2019, EN779:2012 & EN779:2002 – Similar to MERV, this rating was created for consistent air filter testing. The factory test ensures the air filter achieves the specified efficiency of removing debris.

Types of Filters

For most compressed air systems, there is a primary or pre-filter element and a secondary or final filter element. The primary filter is the first line of defense against debris and is typically replaced more often to ensure the highest level of contamination is removed. The secondary filter serves as the second defense catching the smaller particles that made it through the primary filter.

Consider Your Site Conditions

High dust environments like paper mills and textile factories will benefit from higher efficiency and higher micron filters to ensure the air going into the air compressor is free from the debris generated within the factory.

Environments with low dust can use standard air compressor filtration elements with a longer product life than the higher efficiency and higher micron level filters.

New FS-Elliott Air Filter Solutions

We have recently launched our

Change on the Go filters, which allow operators to change the filters without turning off the compressor and disrupting production. These filters are available in standard or extended life options.

Keep in mind that when purchasing an air filter, paying attention to the efficiency rating, filter material, and the efficiency of trapping microns will save you money both in the short and long run. And following OEM guidelines for replacing filters is essential to protecting your investment as well as maintaining air pressure and reliable system operation.

Selecting the Right Air Filter for Your Application

Determining which air filter is right for you depends on your compressor application, what products you produce, the amount of pollution in your operating environment, and specific industry regulations.

Please contact your local

FS-Elliott authorized channel partner for assistance with selecting the right air compressor for you.