As summer temperatures climb, ensuring your centrifugal air compressors are ready for the heat is critical to maintaining system performance and avoiding costly downtime. High temperatures and humidity levels put added stress on your equipment, especially on key components.

FSE-TurboCool® is a family of full synthetic lubricants formulated for use in centrifugal air compressors and designed to provide your compressor with maximum wear protection when temperatures increase.

TurboCool lubricants work to minimize long-term varnish build-up to help prolong the life of centrifugal compressors. This is in stark contrast to other OEM compressor fluids blended to be used across all types of compressors, including rotary and reciprocating.

Why TurboCool® Is the Ideal Lubricant for Summer Compressor Maintenance

Increased heat during the summer can also result in greater humidity levels.

TurboCool lubricants deliver the best water separation capabilities on the market and allows excess moisture that has built up to separate from your oil system.

Key benefits of TurboCool:

- Enhanced wear protection during high-heat operation

- Minimized varnish build-up for cleaner compressor internals

- Superior water separation, reducing moisture-related damage

- Resistance against rust, corrosion, wear, and viscosity dilution

- Stable viscosity, even in extreme conditions

These features help maintain optimal centrifugal compressor performance, reduce long-term maintenance needs, and support more efficient system operation throughout the hottest months of the year.

Summer Compressor Maintenance Tips for Peak Performance

While

selecting the right lubricant is foundational, a proactive maintenance routine is also necessary to ensure your compressors stay reliable and energy-efficient throughout the season. Here are several steps you should add to your summer maintenance checklist:

- Add Lubricant Monitoring to Your Preventative Maintenance Plan

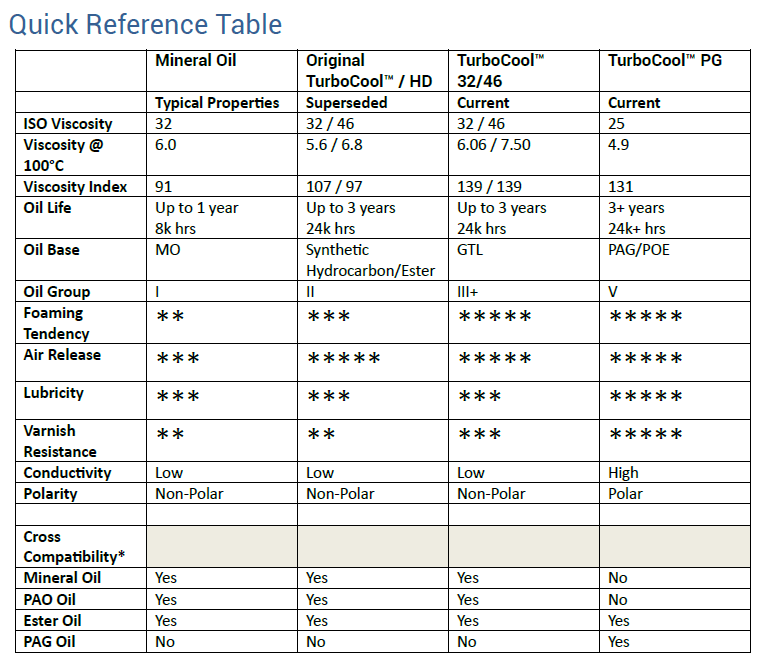

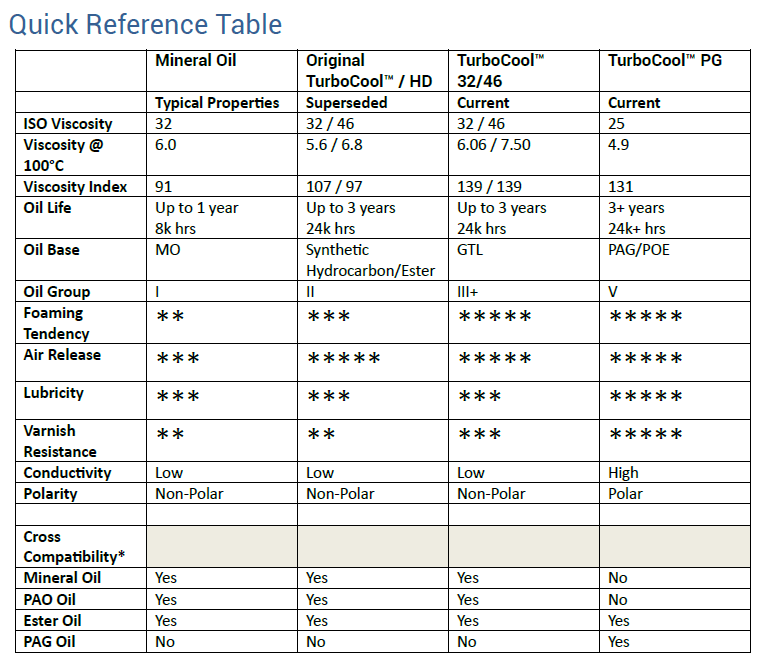

Lubricant testing provides a direct insight into compressor health. Quarterly oil analysis can reveal early warning signs of mechanical wear, contamination, or fluid degradation. Monitoring critical parameters—such as viscosity, acidity, and water content, as shown in the table below—helps you catch potential issues early and extend your unit’s lifespan.

*Click here to see additional guidance from our TurboCool Lubricant Comparison Guide.

- Inspect Auxiliary Oil Pumps and Motor Bearings

Auxiliary oil pump lubrication and motor bearing checks are essential during summer. Increased temperatures can accelerate wear if these components are not properly maintained. Set a regular quarterly schedule to inspect and lubricate these systems.

- Change Your Compressor Lubricant as Scheduled

According to FS-Elliott's OEM maintenance guidelines, TurboCool should be drained, the oil reservoir cleaned, and fresh lubricant refilled every 3 years or up to 24,000 operating hours, whichever comes first.

- Don’t Overlook Oil Filter Changes

Dirty or clogged oil filters force compressors to work harder, generating excess heat and reducing efficiency. To maintain optimal operating conditions, replace OEM oil filter elements every 6 months, as recommended by FS-Elliott.

Protect Your Centrifugal Compressors from Summer Stress

Neglecting lubricant health and regular maintenance during the summer months can result in decreased performance, higher energy usage, and unplanned outages. TurboCool provides industry-leading protection, while a disciplined maintenance strategy ensures your centrifugal compressor system runs efficiently regardless of seasonal challenges.

Need Help Getting Summer-Ready?

For more information on inspecting, maintaining, and operating your compressor at peak efficiency, contact your authorized

FS-Elliott channel partner or sales representative.