Flow rate is one of the most cited and most misunderstood metrics in compressor performance. Terms such as ACFM, SCFM, mass flow, and Free Air Delivery are often used interchangeably, even though they represent fundamentally different measurements. For engineers, plant managers, and decision-makers evaluating air or process gas compressors, understanding how flow is defined and measured is essential, not just for selecting the right machine, but for comparing technologies accurately, validating performance claims, and ensuring the system operates as intended once installed.

If you are unsure which flow measurement to reference when comparing compressors, the best practice is to use SCFM. Standard Cubic Feet per Minute provides normalized conditions, making it the most consistent and reliable baseline for evaluating performance across manufacturers and operating environments.

That said, each flow definition serves a specific purpose. Below, we break down how air and gas flow are measured, why those measurements vary, and how engineers interpret flow data in real-world applications.

Why Flow Measurement Is Inherently Complex

Gas volume changes with pressure, temperature, and composition. As a result, the same compressor can appear to deliver very different flow rates depending on:

- Where the measurement is taken

- What conditions is it measured at

- Whether volume or mass is being measured

This is why flow numbers must always be interpreted in context. From an OEM perspective, a single flow value without defined conditions is incomplete at best, and misleading at worst.

The Three Fundamental Definitions of Flow

Volumetric Flow (Actual Volume Flow)

Volumetric flow describes the physical volume of gas moving through a system per unit time. Typical units include:

- Cubic feet per minute (cfm)

- Meters cubed per hour (m3/hr)

Because gas volume expands or contracts with pressure and temperature, volumetric flow varies throughout a system. It is useful for evaluating duct sizing, velocities, and local system behavior, but it does not reflect the actual gas flow through the system. See the graphic below illustrating that, even though each enclosed box takes up the same amount of physical space, the number of gas particles and the gas properties (temperature and pressure) are very different and not ideal for evaluating the compressor’s output.

|

|

| V = 1 ft3 |

V = 1 ft3 |

| Fewer particles |

More Particles |

| Lower Pressure |

Higher Pressure |

| Lower Temperature |

Higher Temperature |

Mass Flow

Mass flow measures the actual quantity of gas molecules passing through a system, independent of pressure and temperature. Typical units include:

- Kilograms per second (kg/s)

- Pounds per hour (lb/hr)

Mass flow remains constant through compression and expansion and is the most physically accurate way to describe gas movement. For many process gas applications, mass flow is the preferred performance metric because it directly correlates with thermodynamic behavior and the amount of gas the process demands. The image below shows the same number of gas particles before and after compression; although their size and properties have changed, the mass remains constant.

|

|

| V = 1 ft3 |

V = 0.5 ft3 |

| Same particles/mass |

Same particles/mass |

| Lower Pressure |

Higher Pressure |

| Lower Temperature |

Higher Temperature

|

Standardized (Pseudo-Mass) Flow

Standardized flow measures volumetric flow to a defined set of reference conditions (temperature, pressure, relative humidity), allowing volumetric measurements to be compared as if they behaved like mass flow. For those familiar with volume flow, this is the easier-to-understand and more accurate flow measurement. Typical units include:

- SCFM (standard cubic feet per minute)

- Nm³/hr or Nm³/min (normal, metric systems)

By normalizing flow to standard conditions, standardized flow enables fair comparisons between compressors operating under different inlet conditions, elevations, or ambient environments when using the same reference conditions. It uses a volumetric unit to describe the flow rate, but essentially represents a mass flow because the reference condition is defined. This is why it is also known as “pseudo-mass” flow.

Though mass flow better represents the number of gas particles you’re getting out of your compressor, compressors are generally sized by volumetric flow rates. The illustration below shows compressor outputs at the same volumetric flow rate, differing in the number of particles/mass and their respective pressures, temperatures, and relative humidities. At this point, there is little value in comparing the compressor outputs, as their operating conditions differ significantly, leading to varying densities and masses.

|

|

| Flow = 1000 FAD (CFM) |

Flow = 1000 FAD (CFM) |

| Pin = 14.5 PSIA |

Pin = 14.8 PSIA |

| Tin = 85°F |

Tin = 50°F |

| RH = 60% |

RH = 70% |

| Mass Flow = 71.39 lb/min |

Mass Flow = 78.36 lb/min |

However, if we then take these two flows and redefine their volumetric flow rates to a standard set of conditions, say 14.7 PSIA, 60°F, and 0% RH, we can see that their standardized CFM flows are different and thus offer a better comparison of compressor output at multiple operating conditions. Though it is still technically measuring volume, the impacts of pressure, temperature, and relative humidity can be accounted for.

|

|

| Flow = 917.81 SCFM (dry) |

Flow = 1017.91 SCFM (dry) |

| Pin = 14.5 PSIA |

Pin = 14.8 PSIA |

| Tin = 85°F |

Tin = 50°F |

| RH = 60% |

RH = 70% |

| Mass Flow = 71.39 lb/min |

Mass Flow = 78.36 lb/min |

In Summary

- Volumetric flow describes how much space the gas occupies

- Mass flow measures the actual molecules of air moving

- Standardized flow enables consistent comparison across systems by defining the standards by which the flow is measured.

Common Compressor Flow Units Explained

ICFM – Inlet Cubic Feet per Minute

ICFM represents the raw volumetric flow entering the compressor inlet, measured at actual inlet conditions.

- Not adjusted for temperature, pressure, or humidity

- Useful for understanding intake conditions

- Not suitable for performance comparison between differing inlet conditions

ACFM – Actual Cubic Feet per Minute

ACFM represents volumetric flow at a specific point in the system, corrected for the local operating conditions at that location.

- Reflects the real volumetric flow rate at a specific point in the system

- Varies throughout the system due to differences in temperature, pressure, and humidity at different points between the compressor inlet and discharge

- In the compressor industry, the measured point is typically the compressor outlet, while the local conditions are taken at the inlet

- Useful for evaluating velocities, losses, and system design

FAD – Free Air Delivery

Free Air Delivery describes the usable volumetric flow delivered by the compressor, referenced back to defined inlet conditions and accounting for internal losses. It is also known as the delivered air flow at inlet conditions.

- Represents what the compressor actually delivers

- Useful for evaluating real output versus nameplate claims

- Often expressed in cfm or m3/hr

- In the compressor industry, FAD measured in cfm is used interchangeably with ACFM

SCFM – Standard Cubic Feet per Minute

SCFM normalizes flow to standard reference conditions, commonly 14.7 PSIA, 60°F, 0% RH (though definitions may vary).

- Enables fair, apples-to-apples comparisons when the same SCFM definition is used

- Commonly used for ratings and specifications

- Only a valid comparison when the same reference conditions are used

- Metric equivalent: Nm³/hr or Nm³/min

Flow Units at a Glance

| Unit |

Adjusted for Conditions |

Where Measured |

Practical Use |

|

ICFM

|

No

|

Compressor inlet

|

Shows raw intake volume

|

|

ACFM

|

Yes (local pressure/temp/humidity)

|

Any system point

|

Real flow under current conditions

|

|

FAD

|

Yes (to inlet conditions)

|

Compressor output

|

Shows the actual delivered volume

|

|

SFCM

|

Yes (to standard reference)

|

Compressor output

|

Fair comparison across systems

|

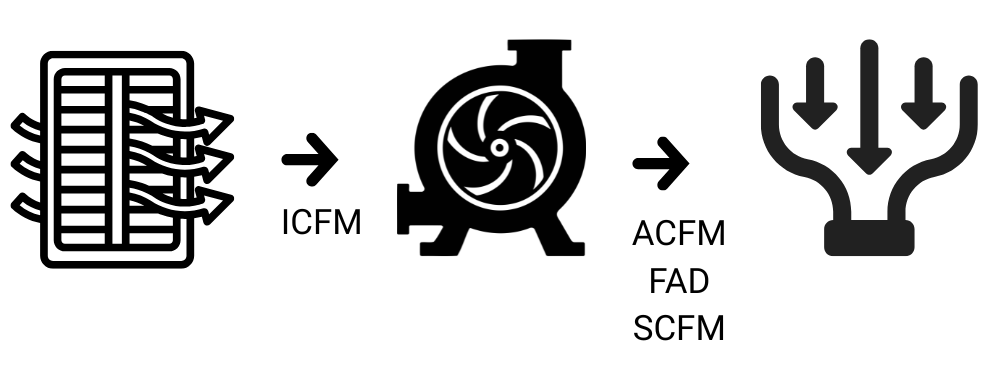

In the context of air compressors specifically, the measuring points for these different flows can be shown as follows:

How OEMs Interpret Flow Data

From a compressor design standpoint, flow values are never evaluated in isolation. Engineers consider:

- Measurement location

- Reference conditions

- Gas composition

- Operating pressure ratio

- System losses

Performance discrepancies almost always trace back to mismatches in flow definitions rather than to equipment shortcomings. Understanding the distinction between flow types leads to better equipment selection, more precise specifications, and smoother commissioning.

Final Takeaway: What This Means for Compressor Selection

Understanding how air and gas flow are defined and measured is essential to making informed compressor decisions. Volumetric flow, mass flow, and standardized flow each serve a distinct purpose, but they are not interchangeable. Using the wrong reference can lead to inaccurate comparisons, misaligned expectations, and avoidable performance gaps all leading to lost production and higher costs.

From an OEM perspective, flow values only have meaning when evaluated in context. Measurement location, reference conditions, gas composition, pressure, and temperature all directly influence how flow should be interpreted. When these factors are clearly defined, compressor performance becomes predictable, comparable, and repeatable, both on paper and in operation.

For engineers and system designers, consistency is the key. Confirm which flow definition is being used and ensure all flow values are expressed on a common basis, using tools like

AeroSwap to quickly convert between flow units and reference conditions before drawing conclusions. This approach leads to better equipment selection, smoother commissioning, and systems that perform exactly as intended.

Frequently Asked Questions (FAQs)

Is this information applicable to both air and gas compressors?

Yes. The principles of volumetric flow, mass flow, and standardized flow apply equally to compressed air and process gas applications. The primary difference lies in gas composition and reference conditions, not the measurement methodology.

Why do two compressors with the same SCFM rating perform differently?

SCFM alone does not capture inlet conditions, gas composition, pressure ratio, system losses, or physical differences between the machines. Two machines may share the same SCFM rating yet deliver different usable outputs under actual operating conditions. If the SCFM definitions are not the same, they are not measuring flow the same.

Should I use ACFM or SCFM when comparing compressors?

SCFM is best for comparing compressors across different environments. ACFM is more useful for analyzing flow at a specific point within a system. However, be aware that there are multiple standard conditions being used as the definition for SCFM. Different standard conditions impact the value of SCFM because the basis is different.

Below shows examples of how the same flow rate changes in measured SCFM when the standard condition varies.

| Flow Unit |

Value |

Standard Condition Definition |

|

ACFM*

|

1000

|

-

|

|

SCFM

|

905

|

14.7 PSI(A) / 60F / 0% RH

|

|

SCFM

|

923

|

14.7 PSI(A) / 70F / 0% RH

|

|

SCFM

|

919

|

14.7 PSI(A) / 68F / 0% RH

|

|

SCFM

|

918

|

14.5 PSI(A) / 60F / 0% RH

|

|

SCFM

|

932

|

14.5 PSI(A) / 68F / 0% RH

|

*At the compressor outlet, defined to specified inlet conditions of 14.7 PSI(A), 95Ö¯F, 60% RH

Is mass flow more accurate than SCFM?

Mass flow is the most physically accurate representation of the movement of the gas molecules. SCFM approximates mass flow by normalizing volumetric flow to standard conditions, making it easier to use for comparisons and specifications.

What flow unit should be used for system design?

System design typically relies on ACFM because it reflects the actual conditions at each point in the system. Compressor selection and comparison generally rely on SCFM or delivered volumetric flow.

Why does the inlet condition matter so much?

Inlet pressure, temperature, and gas composition directly affect density. Even minor deviations from reference conditions can significantly change volumetric flow values and perceived compressor capacity. See below for illustrations showing the effect of temperature on density. The same mass of air occupies different volumes at different temperatures.