Is your

centrifugal compressor falling short or driving up energy costs? Even the most durable compressor airends experience wear over time. Left unaddressed, this can result in declining efficiency, rising energy consumption, and the risk of unexpected downtime. Because these issues often develop gradually, it is essential to recognize the warning signs early and take corrective action before they affect your operations.

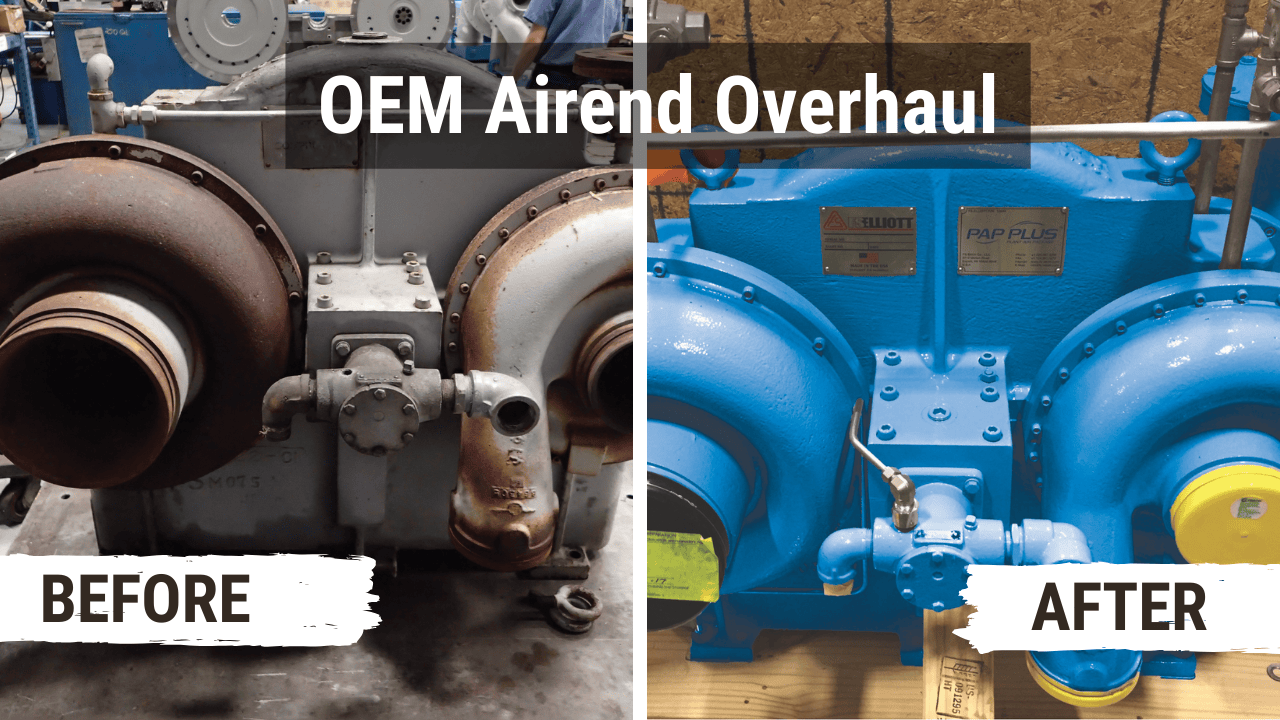

Through FS-Elliott’s factory-certified overhaul services, your compressor's removable airend can be restored to peak performance, extending the life of your capital investment, while reducing the risk of costly downtime. Discover the five key signs it's time to act, and why choosing FS-Elliott’s OEM expertise delivers exceptional long-term value.

Sign 1: Inability to Meet Air Demand

Struggling to maintain pressure or meet air demand? Over time, normal wear on critical airend components such as seals, impellers, and diffusers can lead to performance impacts. These impacts could result in a loss of flow and difficulty in reaching the design setpoints. If performance has degraded and routine maintenance steps are not resolving the issue, an overhaul may be necessary to restore the airend to its original design standards.

Sign 2: Rising Energy Consumption

Noticing higher energy costs without an increase in demand? A worn airend forces the compressor to work harder, increasing kW per CFM. This is often caused by unbalanced or degraded rotating components.

Sign 3: Increased Vibration Levels

Excessive vibration is one of the clearest signs that an overhaul is overdue. These symptoms typically point to deeper mechanical issues, such as worn bearings or rotor imbalance. Left unchecked, vibrations can accelerate wear or result in failures, leading to unplanned downtime. Acting early with a proper overhaul helps prevent costly downtime and ensures that your system operates smoothly.

Sign 4: Higher Operating Temperatures

Is your compressor running hotter than usual, even with clean coolers and proper oil flow? Elevated discharge or bearing temperatures often signal an increase in cooling fouling, compromising heat transfer efficiency. A properly timed overhaul can restore component tolerances and cooling performance, avoiding heat-related failures.

Sign 5: Frequent Control Adjustments

An increase in compressor surge events and frequent operator setpoint changes often point to underlying performance degradation. In some cases, discharge air pressure may exceed system capabilities due to wear on internal components, such as impellers, seals, or diffusers. These conditions not only impact efficiency but also increase the risk of mechanical failure. Scheduling a properly timed overhaul can help limit surge events and reduce the need for constant operator intervention, ultimately supporting maximum uptime, stable performance, and energy efficiency.

The FS-Elliott Advantage

Centrifugal compressors demand precision, and restoring them isn’t a job for just anyone. FS-Elliott brings unmatched expertise, rebuilding your airend to exact factory specifications using the same engineering insights that shaped its original design. With genuine parts, rigorous testing, and OEM-backed support, we deliver reliability you can count on.

The Results You Can Expect

- Factory expertise and exact fit - As the original manufacturer, we know your equipment inside and out. Every overhaul adheres to strict OEM tolerances, utilizing genuine FS-Elliott components for long-term reliability and optimal performance.

- Rigorous testing and quality assurance - Each overhauled airend is fully disassembled, cleaned, balanced, reassembled, and performance-tested, ensuring it meets or exceeds original design standards.

- Rapid turnaround, less downtime - Our Rapid Response Service Center expedites overhaul timelines, and our removable airend design enables faster and less disruptive field servicing, minimizing disruptions to your operations.

- OEM warranty and long-term support - Unlike third-party providers, we stand behind our work with warranty protection and full lifecycle support, offering unmatched peace of mind.

- Sustainable and cost-effective - An overhaul helps reduce waste, supports ESG initiatives, and avoids the cost of full compressor replacement, all while maximizing ROI and equipment life.

Plan Ahead to Protect Performance

Don’t wait for symptoms. Plan your overhaul on your terms, and keep your system running like the day it was installed. An airend overhaul from FS-Elliott helps you:

- Avoid emergency shutdowns

- Regain lost capacity and efficiency

- Extend the life of your compressor

- Reduce long-term maintenance and energy costs

Even if your compressor seems to be running fine, a proactive health check can uncover hidden issues, keeping you running when uptime matters most.

Ready to Review Your Airend’s Health?

FS-Elliott’s certified experts can evaluate your airend and recommend the right path forward. Whether you need a full overhaul or a performance assessment, we’re here to help you make a confident, cost-effective decision.

View our Airend Solutions brochure to explore our capabilities, or contact us to schedule a compressor health review today.