In-house comparison of FS-Elliott OEM oil filter (P3516C160-3) vs. one 3rd party ‘compatible’ filter.

At first glance, the OEM and aftermarket filters may appear similar in size, suggesting they’re interchangeable. However, a closer inspection reveals a noteworthy weight difference, indicating the OEM filter likely uses more robust materials, thicker components, and stronger overall construction. These distinctions aren’t just cosmetic, they’re critical to ensuring long-term compressor performance, reliability, and warranty protection.

Let’s take a closer look at the construction details to see why these differences matter for compressor performance and reliability.

What We Found – And Why It Matters

Weight

.png)

Findings:

- FS-Elliott filter is 1.5 oz heavier; likely thicker, stronger canister.

Possible Risks:

- Lighter housings may rupture under pressure spikes; rapid oil loss and possible downtime.

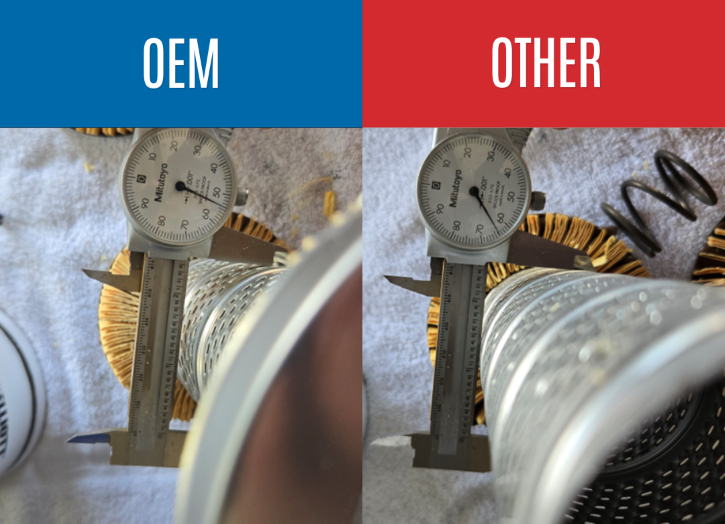

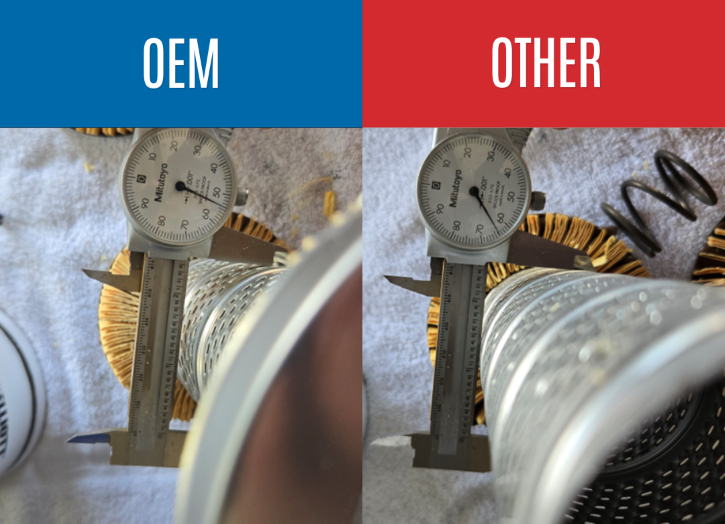

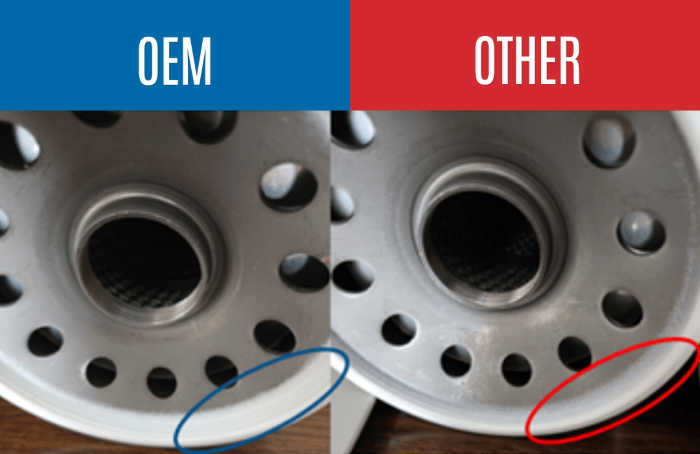

Canister & Flange

Findings:

- FS-Elliott canister wall ~.005–.006" thicker.

- FS-Elliott flange appears slightly wider.

Possible Risks:

- Thinner wall lowers burst-pressure margin; risk of canister deformation or rupture under load.

- Narrower flange can compromise sealing surface; oil bypass at the gasket.

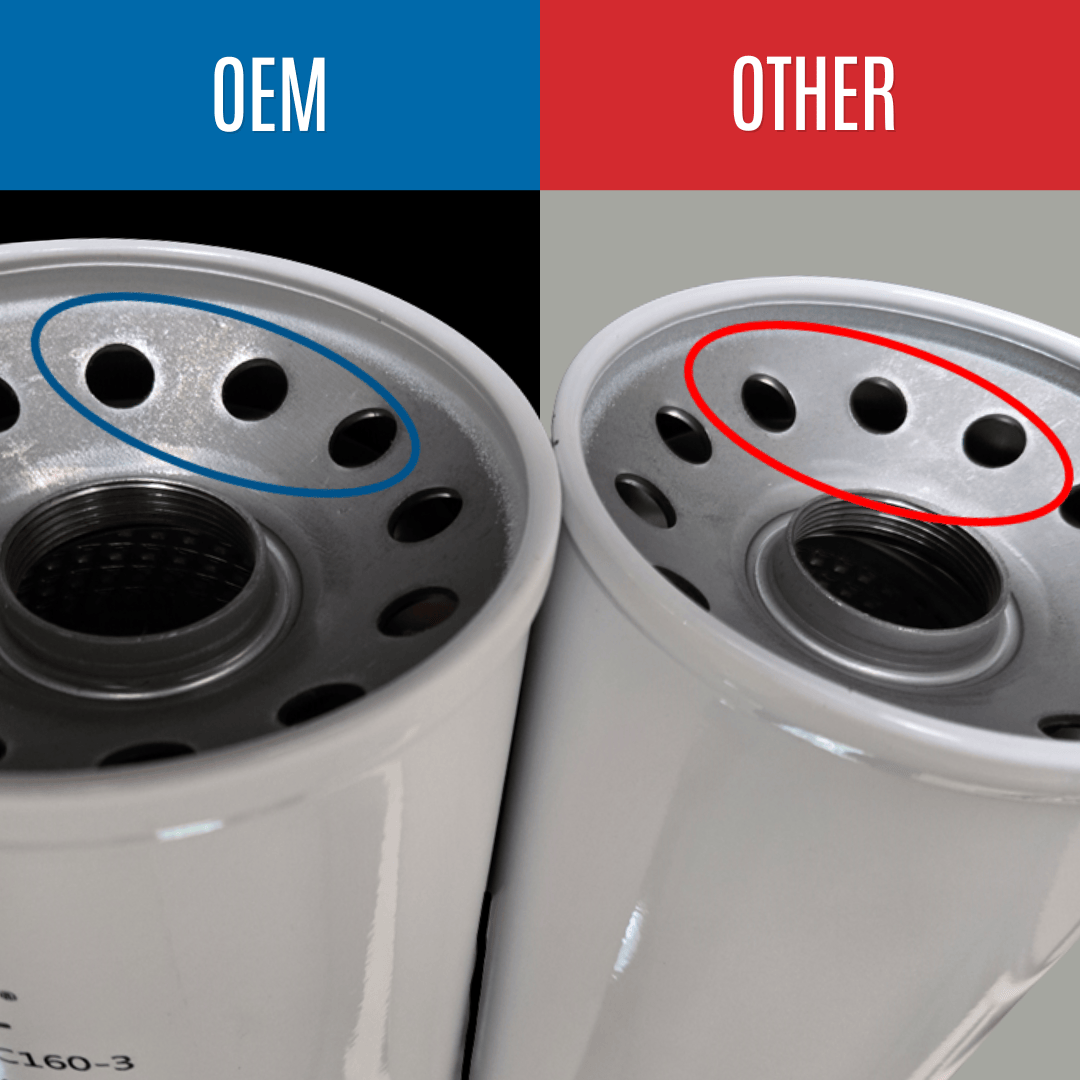

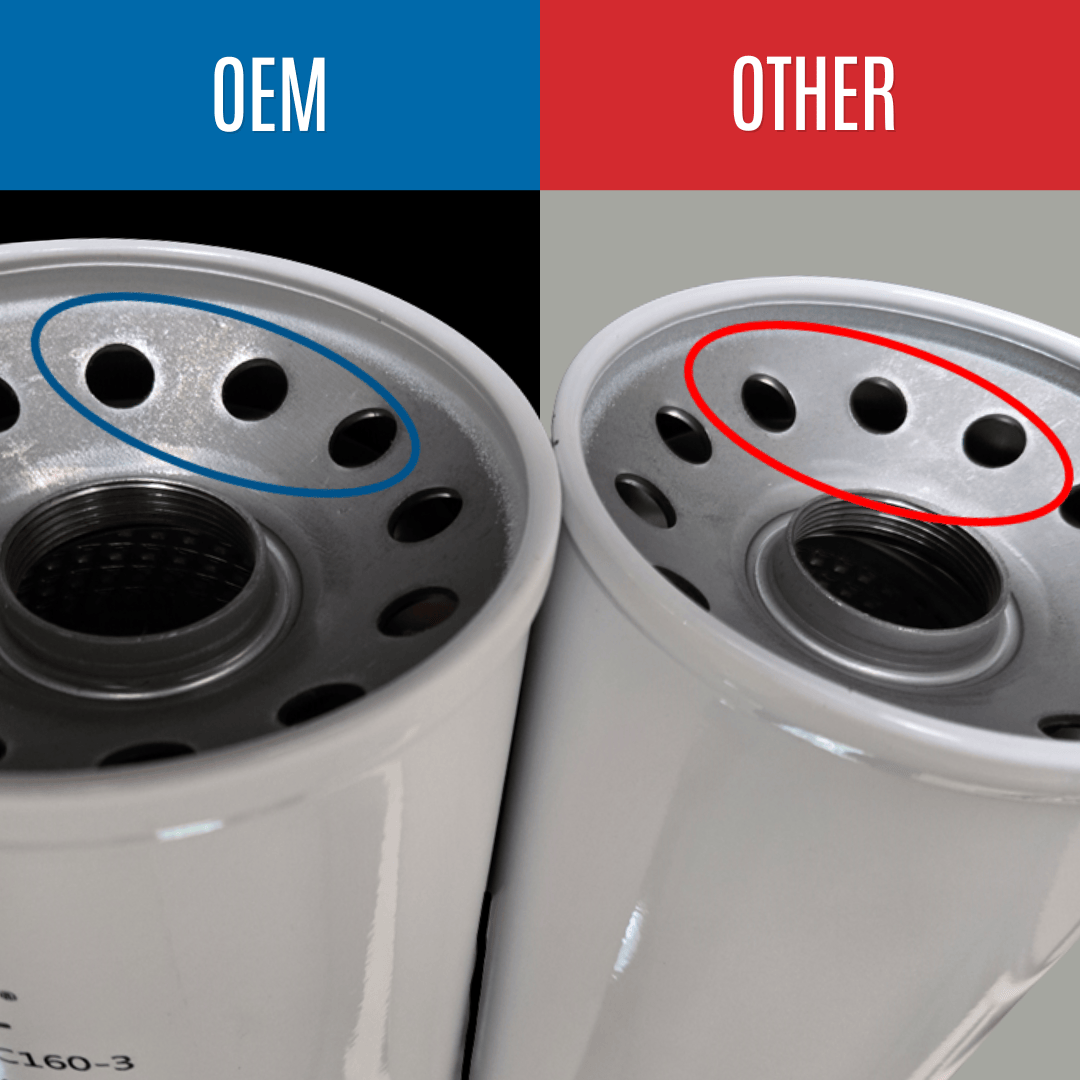

Inlet Holes (Deburring)

Findings:

- FS-Elliott inlet holes deburred; non-OEM shows punch ridges.

Possible Risks:

- Burrs can shed metal into the oil circuit; bearing/gear wear.

- Higher flow restriction at sharp edges can increase pressure drop across the filter.

Pressure Spring (Bypass Behavior)

Findings:

- Springs look similar; FS-Elliott spring ~.027" shorter.

Possible Risks:

- Wrong spring free length/setpoint can trigger premature bypass (sending unfiltered oil) or delay bypass (oil starvation at cold start/high load).

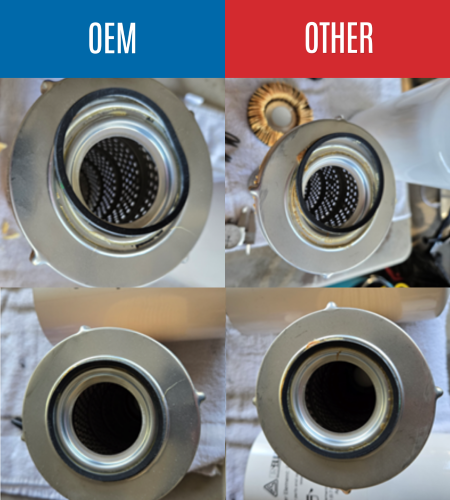

Element Media & Adhesive

Findings:

- Media thickness: FS-Elliott slightly heavier by ~.002–.003".

- Pleat count equal (70) and length similar.

- FS-Elliott glue application is neat; non-OEM glue is sloppy.

Possible Risks:

- Thinner/softer media can collapse under differential pressure; contaminant breakthrough.

- Poor adhesive bonds risk media detachment, allowing unfiltered oil to bypass the element.

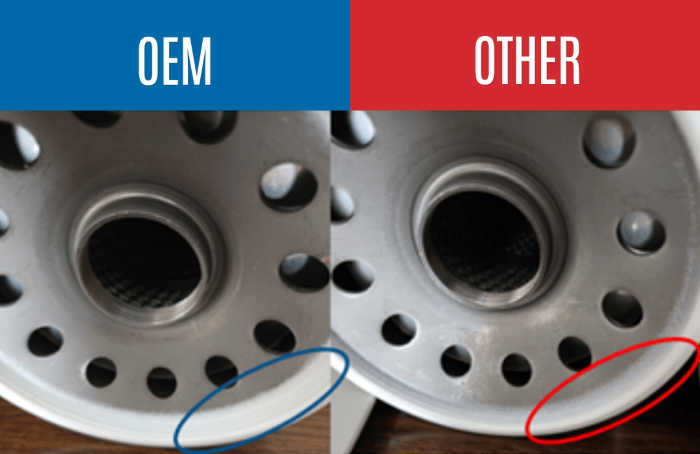

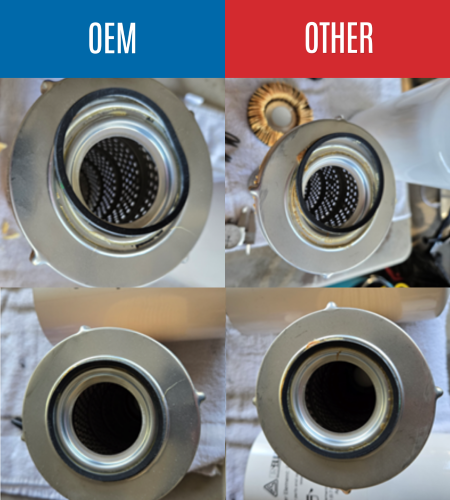

Internal Cage (Support & Integrity)

Findings:

- FS-Elliott cage diameter ~.009" smaller; remained intact after element removal.

- Non-OEM cage end fell apart during removal.

Possible Risks:

- Weak cage support can deform or fragment; debris circulated in the oil stream, scoring precision components.

- Loss of support increases risk of media collapse.

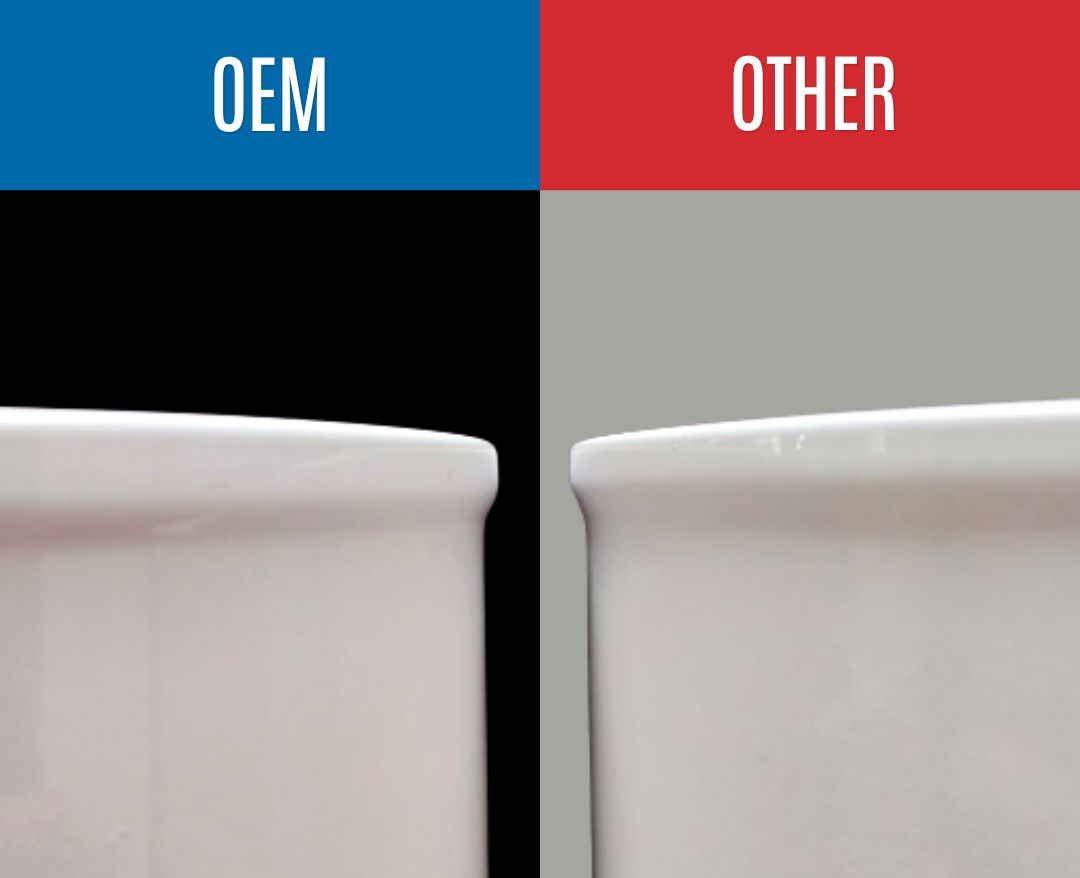

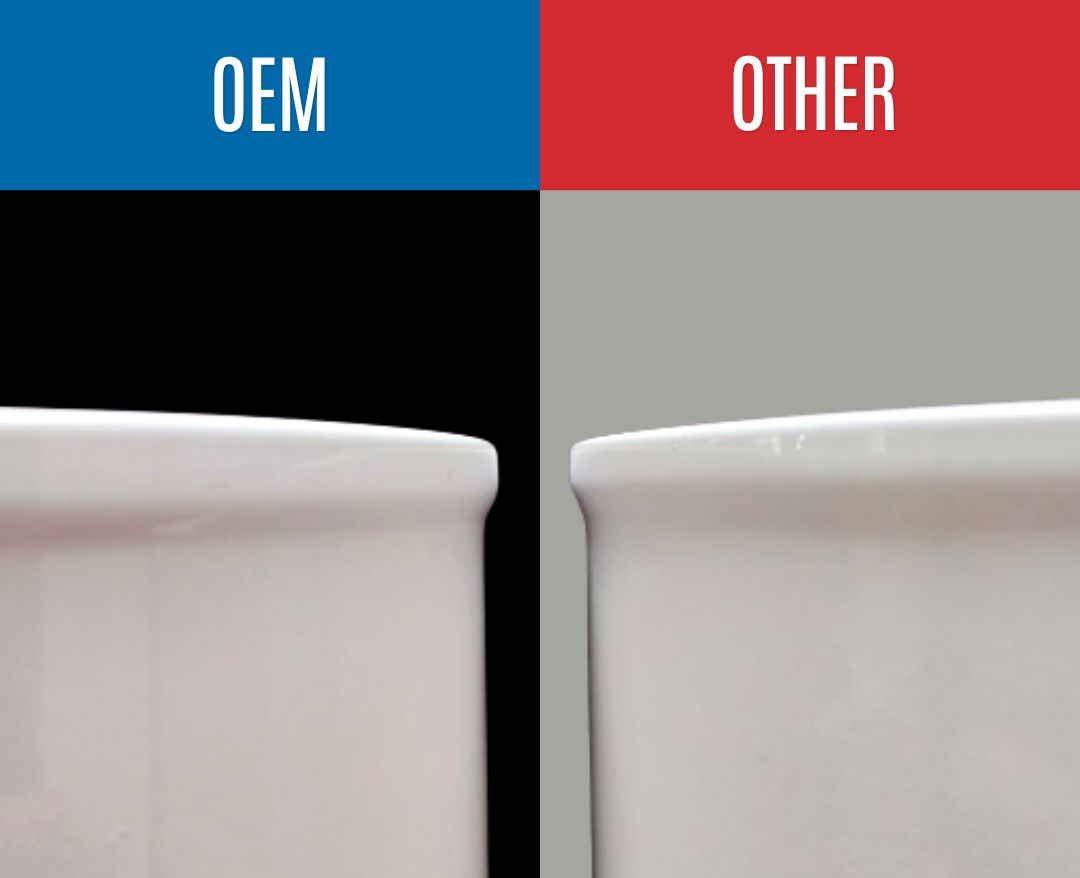

Sealing Side Coating (Overspray)

Findings:

- FS-Elliott shows slightly heavier overspray on sealing side.

Possible Risks:

- Inconsistent coating/overspray control can cause uneven sealing surfaces; gasket leak paths and internal bypass.

O-Rings & Adhesive

Findings:

- FS-Elliott used less adhesive; O-ring tore on removal (stronger bond).

- Non-OEM O-ring peeled off easily; adhesive chemistry appears different.

Possible Risks:

- Weak bonding can let the O-ring shift under pulsation; sudden loss of oil pressure.

- Incompatible adhesive may soften or creep at temperature, compromising the seal.

Appearance, Labeling & Traceability

Findings:

- Different lot numbers; non-OEM canister unlabeled versus FS-Elliott’s clear OEM label.

Possible Risks:

- Lack of traceability complicates failure analysis and accountability; raises counterfeit/spec-compliance concerns.

Spotting a Non-OEM and What to Watch Out For

- Spelling errors or missing trademarks on the canister

- Multiple OEM part numbers listed on a single filter

- No mention of manufacturer or unclear origin

- Lack of published performance specs or certifications

- Claims of “compatibility” without testing validation

Consider Warranty Implications

Using non-OEM parts can do more than compromise performance. It can also void your coverage under FS-Elliott’s SteadiAIR extended warranty program. SteadiAIR is a free program that extends airend coverage for an additional three years beyond the standard two-year manufacturer warranty, providing a total of five years of protection.

Eligibility requires following SteadiAIR guidelines, which include the exclusive use of genuine FS-Elliott parts. This ensures your compressor stays protected, performs at its best, and remains fully covered.

Protect Your Investment, Don’t Risk It on Lookalikes

Heavier and higher quality components minimize pressure drop, prevent leaks, and enhance durability under high-pressure or high-vibration conditions, extending service life and reducing maintenance frequency. In contrast, lighter aftermarket filters may use thinner materials or generic designs, risking reduced filtration, faster clogging, or seal failure, which can lead to inefficiencies, increased wear, or even voided warranties. For optimal compressor performance, especially in demanding environments, FS-Elliott OEM filters are the smarter choice!

Genuine FS-Elliott filters are engineered to our compressor specifications, verified through OEM testing, built with high-grade materials, and backed by our warranty and global support network. Protect your equipment and your schedule by sourcing parts through your authorized

FS-Elliott channel partner, the only true and verified source for OEM parts.

.png)